Sinking EDM

Sinking using electric shocks is an effective solution for removing material from a part. It achieves high precision on all types of materials, regardless of their hardness. Thanks to our equipped machine, we can produce parts in series or in prototype with a precision of up to X mm.

Why choose Die Sinking EDM?

A foolproof method

Realization of various complex shapes

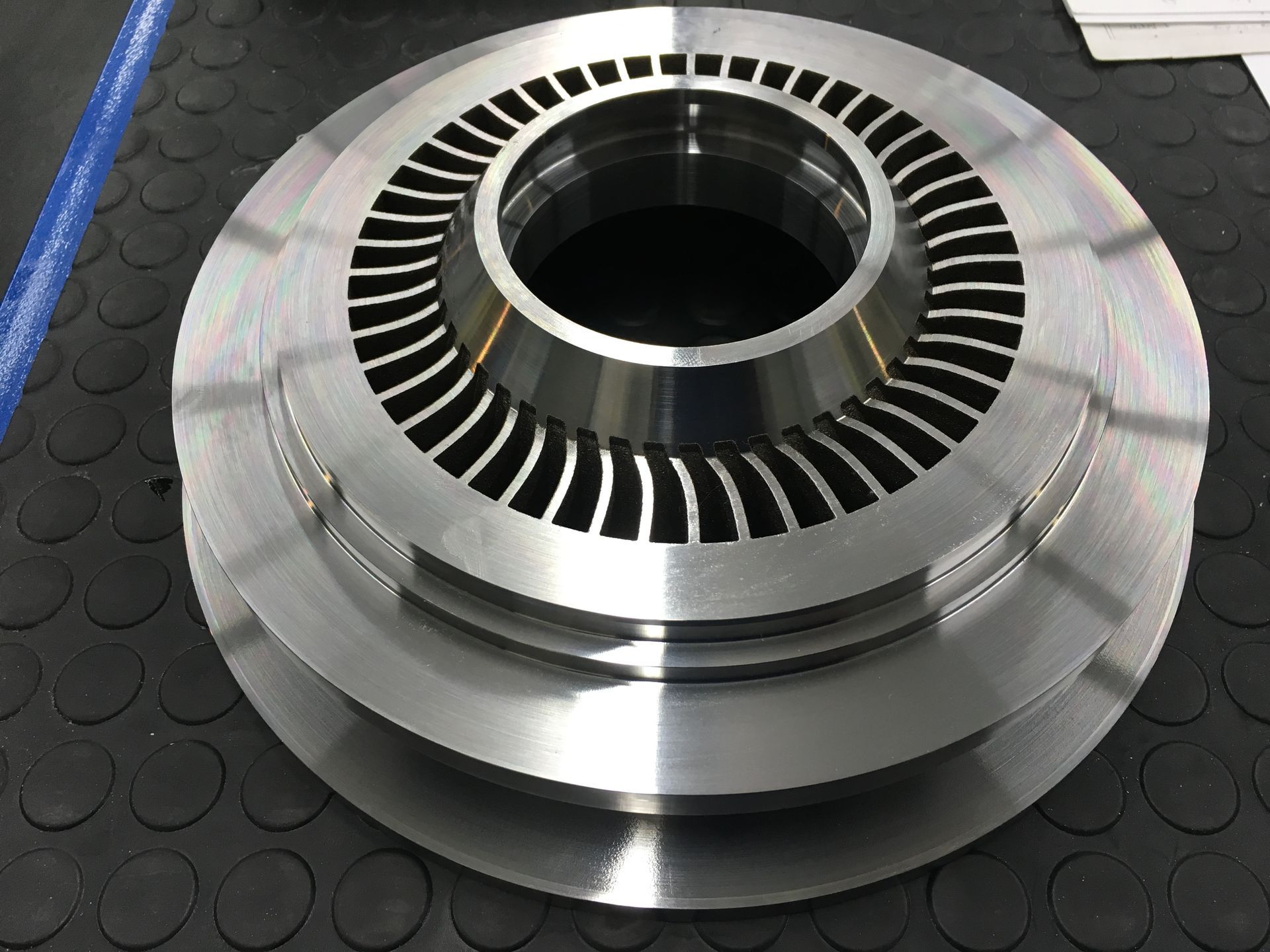

This machining method allows the realization of complex shapes without constraint, which makes it an ideal choice for demanding applications.

No constraints

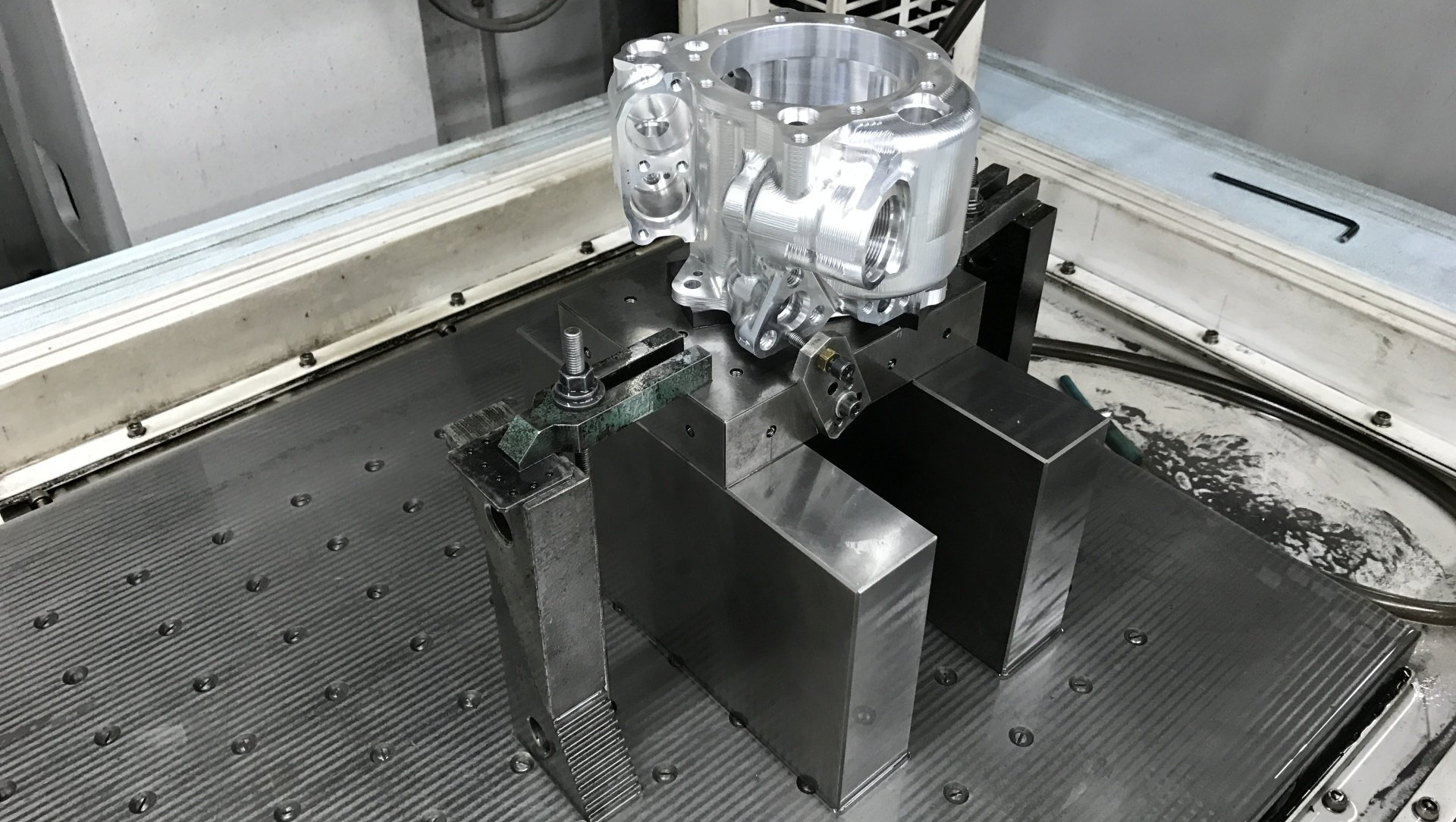

This machining method is unconstrained for the realization of complex shapes due to its efficiency and its ability to produce large quantities of parts with high precision in a short time.

Perfect repeatability

Die sinking EDM offers high repeatability for making complex shapes, which can be crucial in ensuring the quality and accuracy of the parts produced.

How does die sinking EDM work?

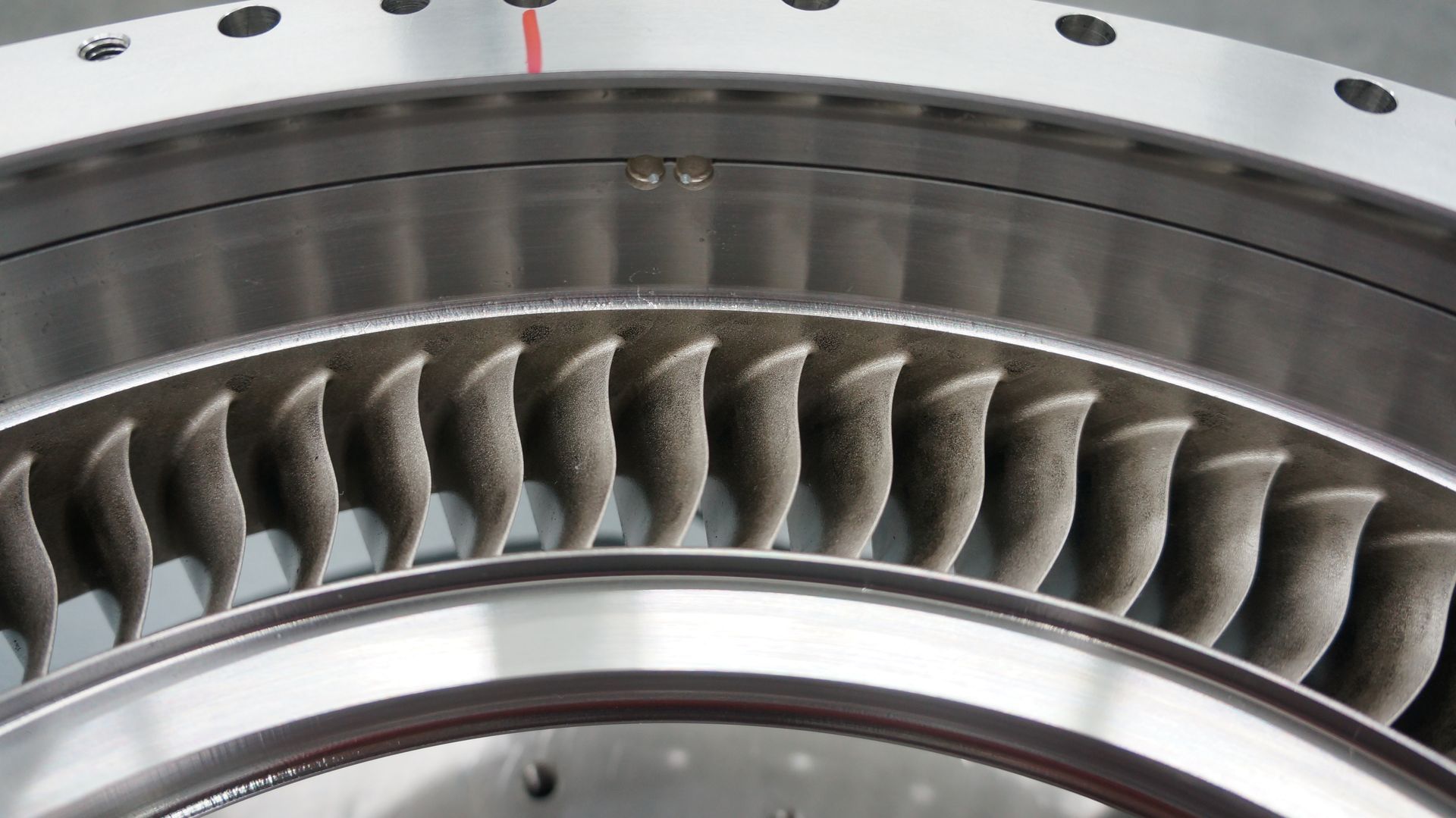

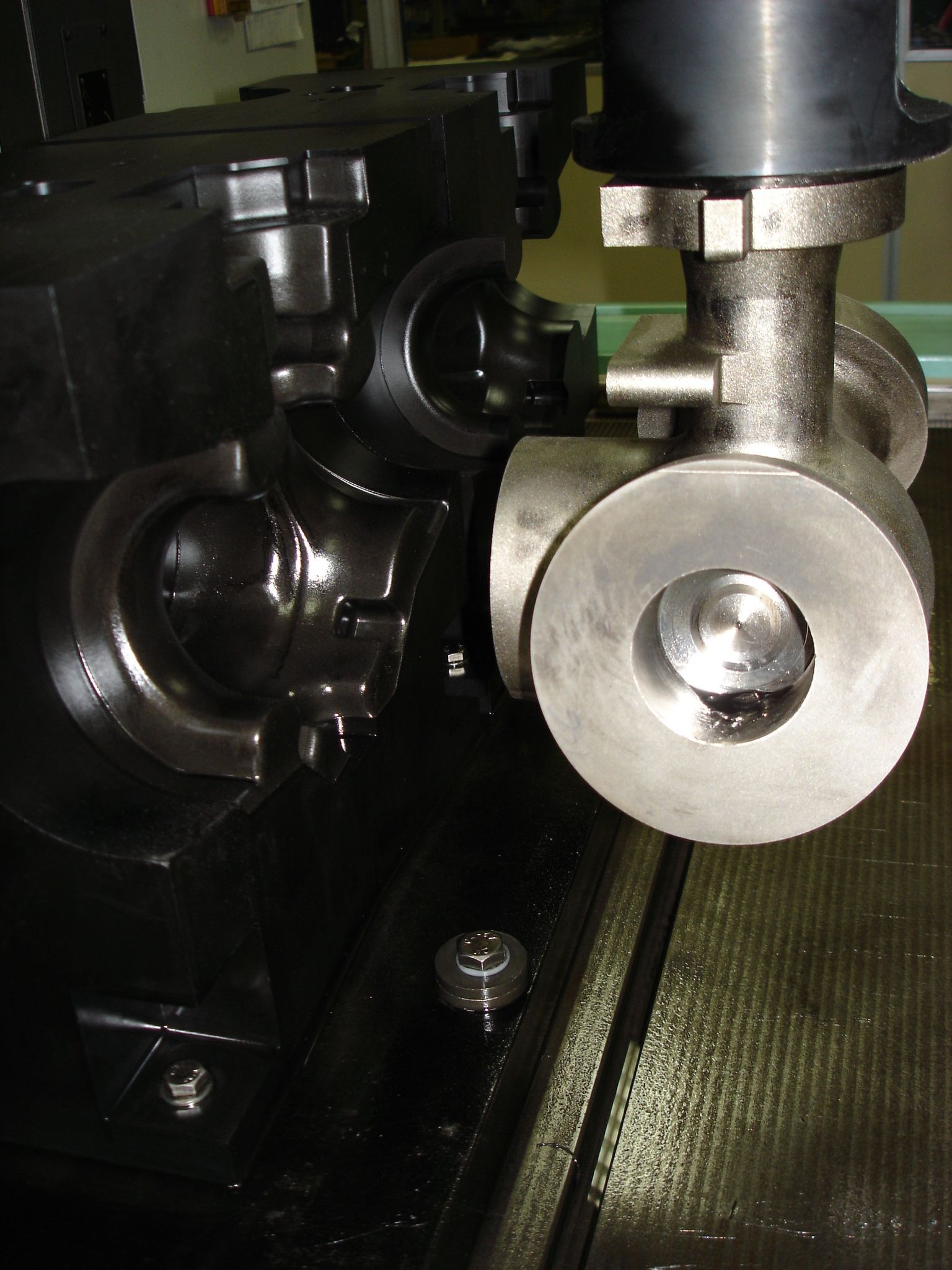

Die-sinking EDM immerses the metal to be machined, called the part, in an insulating liquid. An electrical conductor called an electrode is also immersed.

The electrode and the workpiece are connected to a power supply which generates an electric potential between the two parts. As the electrode approaches the workpiece, a rupture occurs in the fluid, forming a plasma channel, and a small spark jumps from the electrode to the workpiece.

As the base metal erodes from the sparks and the gap between the electrode and workpiece increases, the electrode automatically lowers so the process can continue uninterrupted. Several hundred thousand sparks occur per second.

When to use die sinking EDM?

Die sinking EDM is used for machining complex metal parts that are difficult to produce by other methods. It is particularly useful in the following cases:

- Machining of complex shapes: Die sinking EDM is capable of producing complex and precise shapes, which would be difficult to produce by other machining methods. Machining of hard materials: It is capable of cutting hard materials such as as stainless steel, titanium, etc. without altering their mechanical properties.Precision: It allows the shape of the part to be controlled with high precision, in thousandths of a millimeter, which is important for high precision applications.Mass production: It can be used for production in series of complex parts, with high repeatability and uniform quality. Internal machining: It is able to machine interior cavities that are difficult to access.

In summary, die sinking EDM is a flexible and powerful machining process, which can be used to produce complex and precise parts, especially serial parts, and to machine hard materials with high precision.