Micro-drilling

Micro-drilling is a reliable process for drilling solid metal alloys to very small dimensions. However, it requires great expertise to be performed successfully. Our experts have the necessary technical skills to meet the requirements of this drilling technique.

Why choose micro-drilling?

Quality in a method

Unique reliability

Regardless of the strength of the support, micro-drilling guarantees you a reliable result faithful to your data on a variety of materials, including metals, plastics, glasses and composite materials.

Fast detail work

Micro-drilling is often faster than other drilling methods for small holes. It makes it possible to make precise holes of small size in fine materials without damaging them.

Quality assured

Holes drilled by micro-drilling are cleaner and smoother than those drilled by other methods, ensuring higher quality finished products.

How does micro-drilling work?

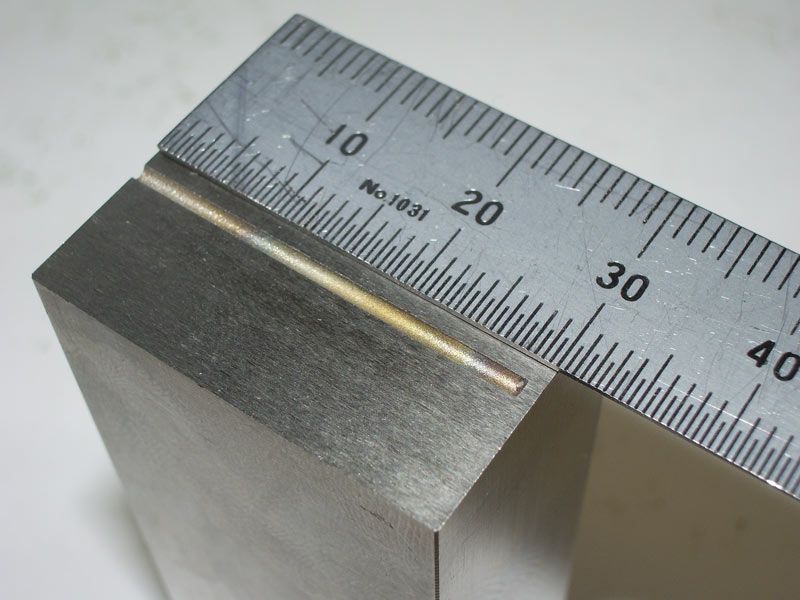

Micro-drilling is a very precise drilling process that uses a very fine drilling tool and a specially designed machine. The part to be drilled is held in place with a center pin and is rotated rapidly while being slowly advanced towards the drilling tool. The cutting force is produced by the interaction between the cutting edges of the tool and the surface of the part, creating a small piece of material which is removed from the part. The shape and dimensions of the hole depend on the shape and geometry of the drilling tool and the relative motion between the tool and the part.

The quality of the hole finish depends on the tool's RPM and feed rate, as well as the cutting temperature and lubrication. To obtain the best results, it is important to control these parameters precisely. By using high-quality drilling tools and high-precision micro-drilling machines, accurate and repeatable results can be achieved.

When to use micro-drilling?

Micro-drilling is used to precisely drill thin and delicate materials without damaging them. This technique is frequently used in the electronics, medical and aerospace industries for applications requiring tiny holes with high precision.